Packaging

We design suitable workplace solutions, modify and deliver individual devices made locally or abroad, assemble entire lines and put them into operation. It goes without saying that servicing is carried out by our trained and qualified staff.

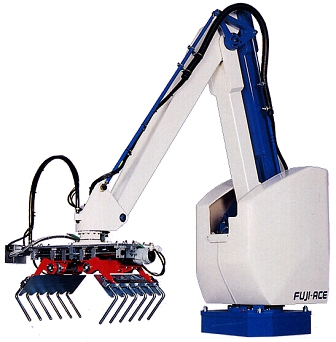

Our advantages include extensive knowledge and experience in handling powder materials and granules. In this area, we supply bag and big-bag fillers, either separately or as part of complete lines, palletising robots, conveyors necessary for the interconnection of the devices, and other accessories (bag feeders, dispensers, labelling machines, packing machines, etc.) as per customers´ wishes and requirements. n ;

The particular type of bag depends on individual needs and requirements - from valve bags, open bags (individual pieces or from an infinite strip) through to bags made off flat plastic films. We fill big bags both with and without inner linings. There are also different types of bag closing systems.