Discharge of tanks and silos

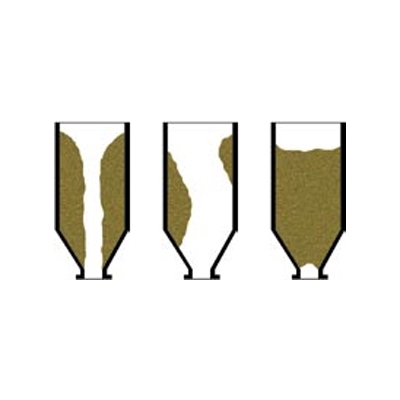

For the discharge of material from storage tanks, there are systems available which are based on releasing the product by compressed air. In comparison to other systems, these systems are more considerate in terms of noise and mechanical damage to the tank case. We offer different solutions based on the characteristics of the product stored.

For fine products, with granulometry in micrometres and millimetres, we use Vibra-Disc nozzles with a unique ability to direct the flow of air along the inner wall of the tank, thus effectively releasing the arch.

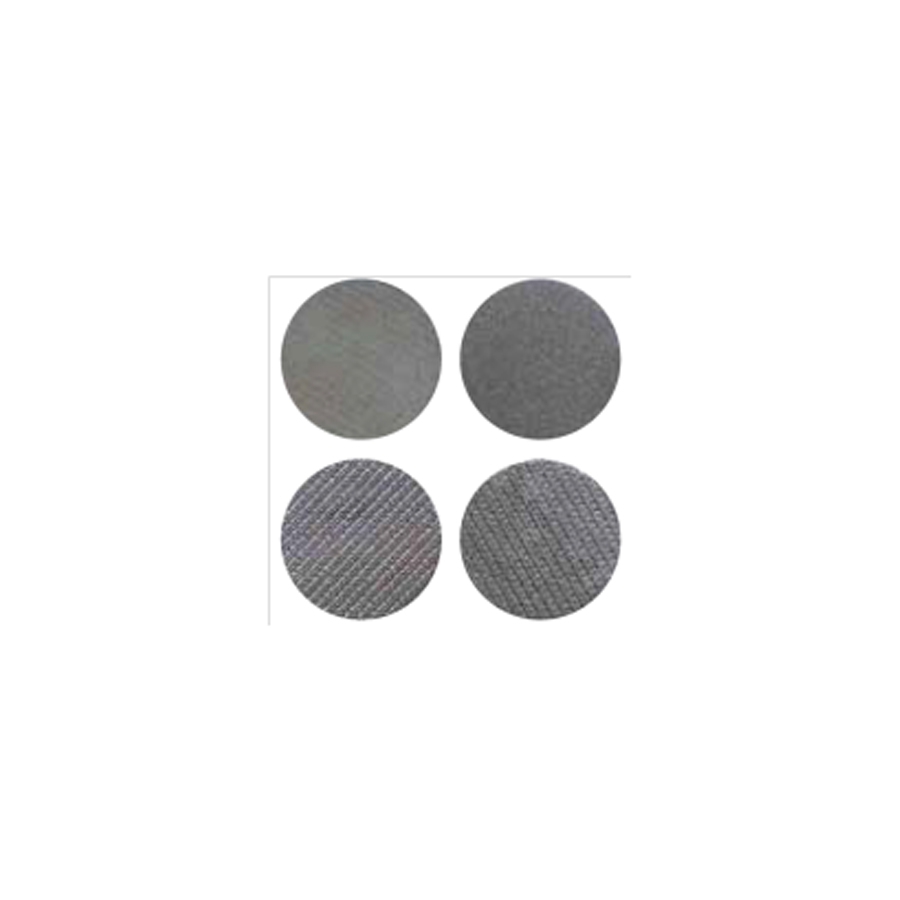

Products with a larger granulometry can be released with TVS nozzles, or with air cannons using impact energy at instantaneous expansion. Special applications which need to be fluidised, or where the product e.g. needs to be left to dry completely during discharge, can be dealt with using Dynapore porous material.

All the systems can be used with air or inert gas when the equipment needs to be run in an environment where there is a risk of explosion.