Sampling

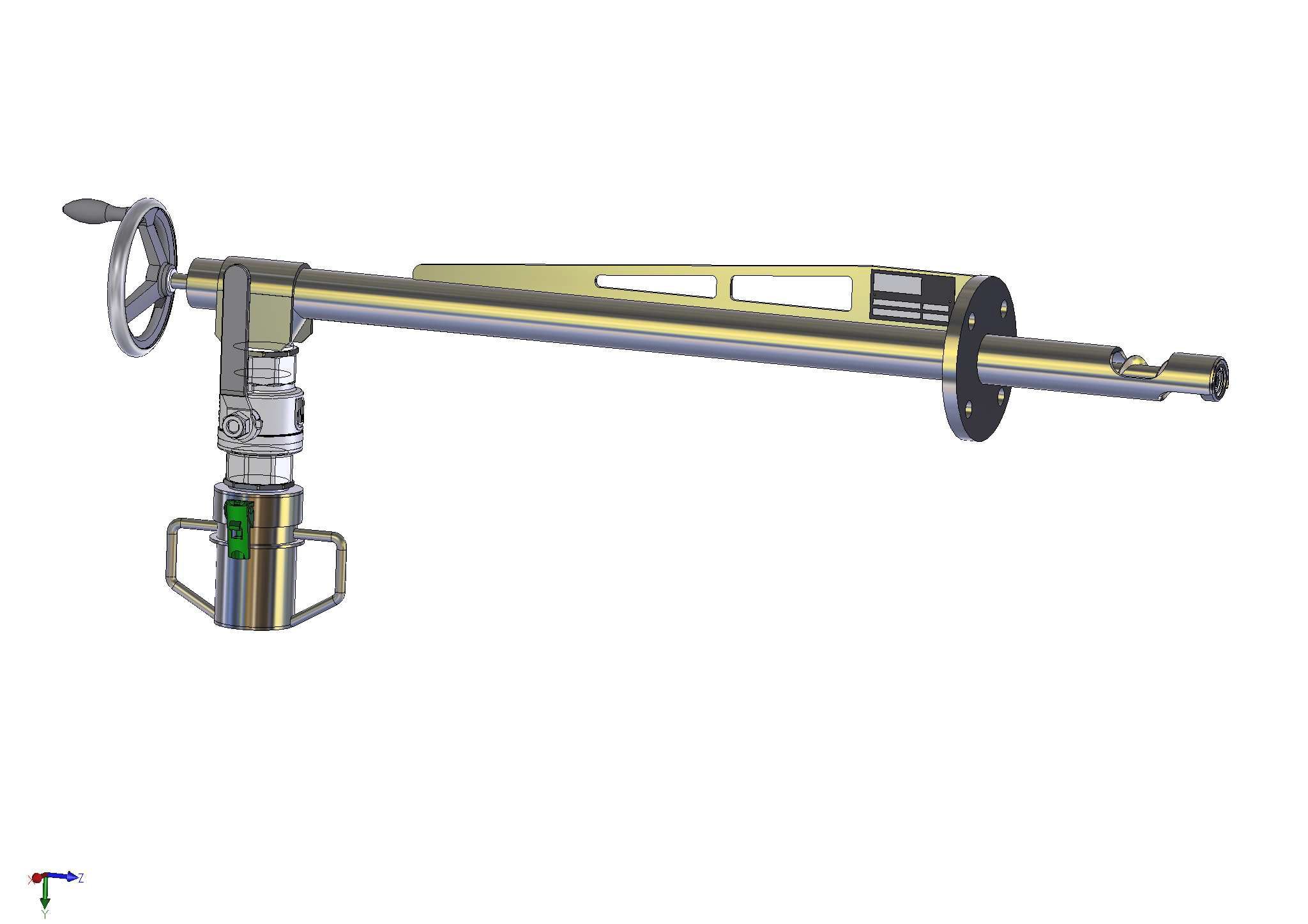

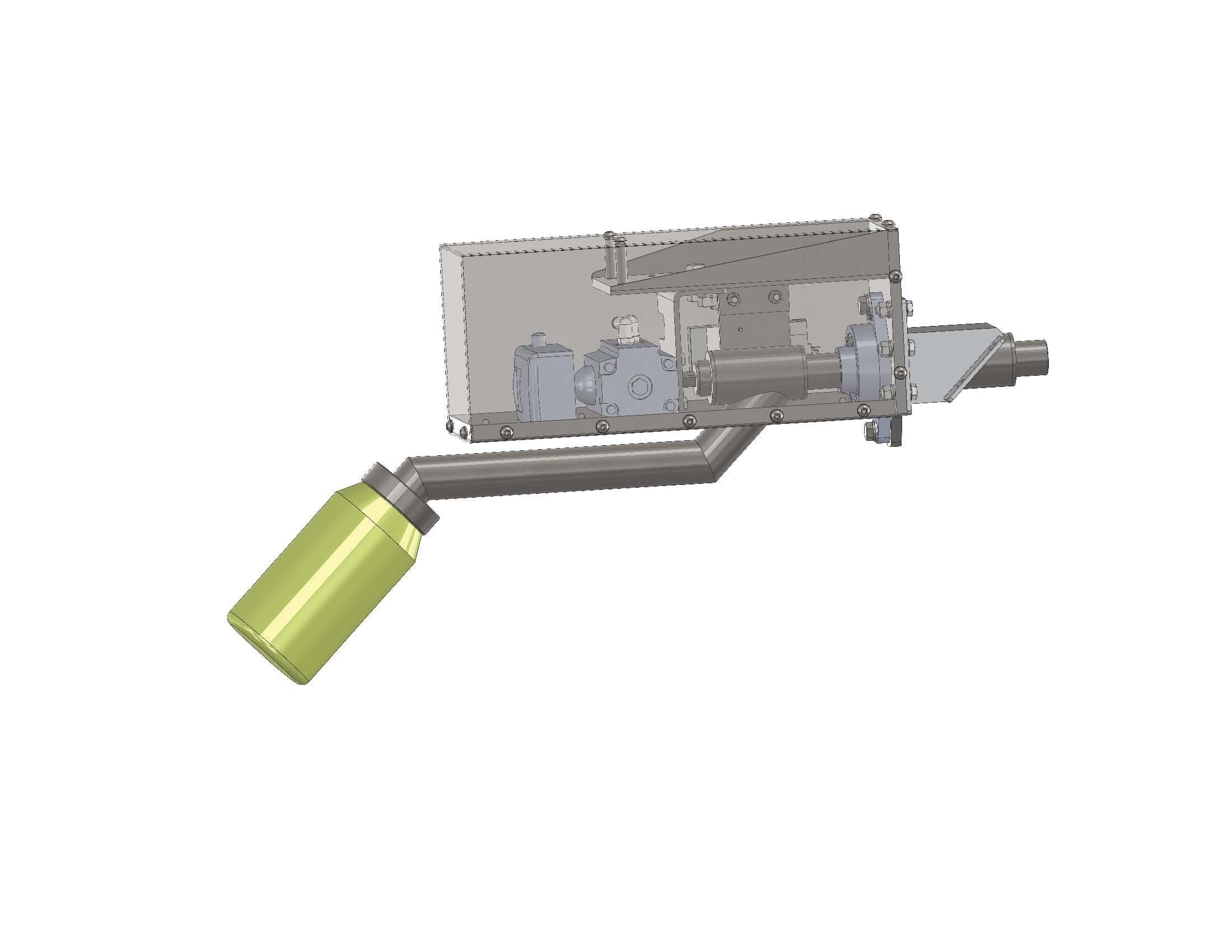

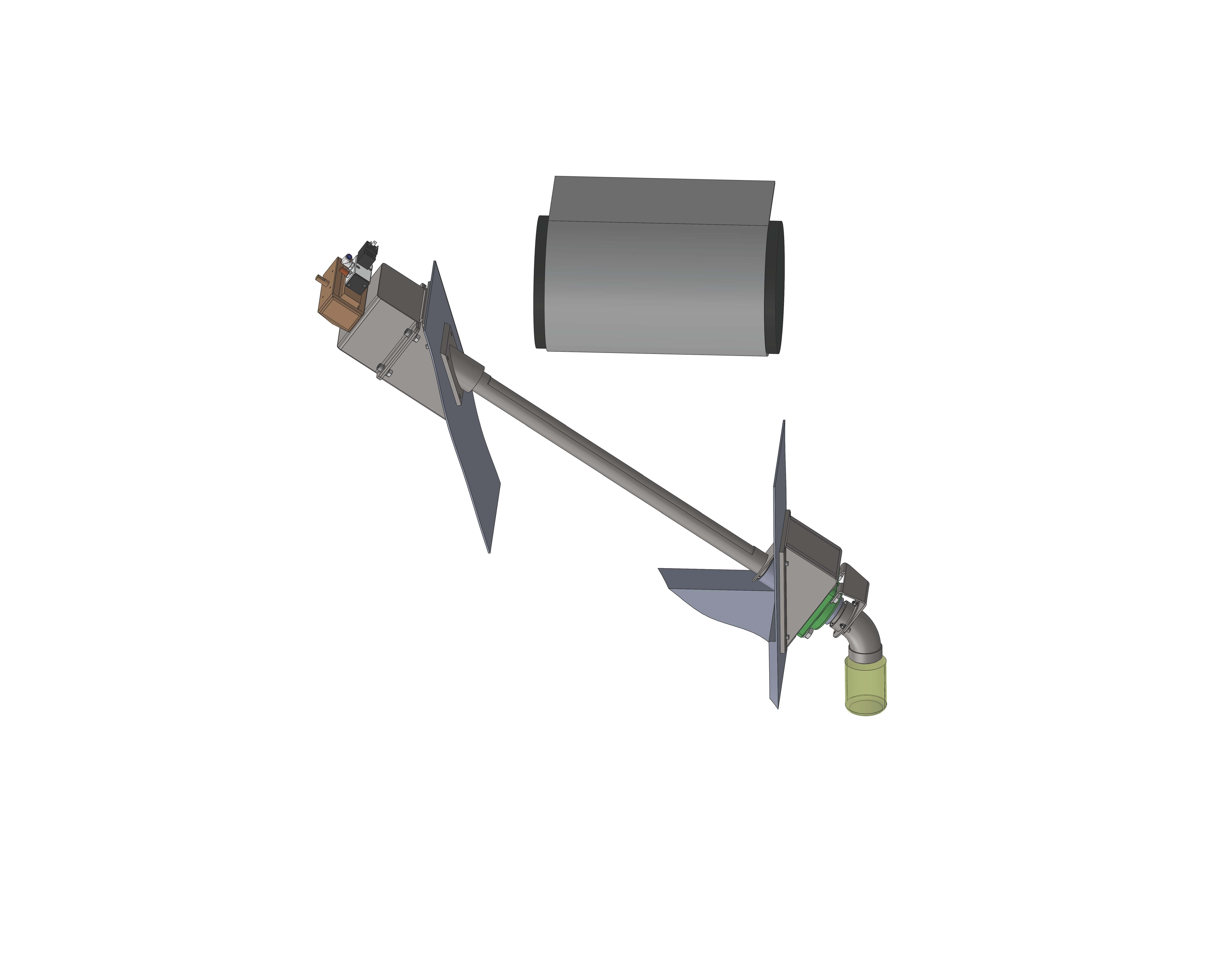

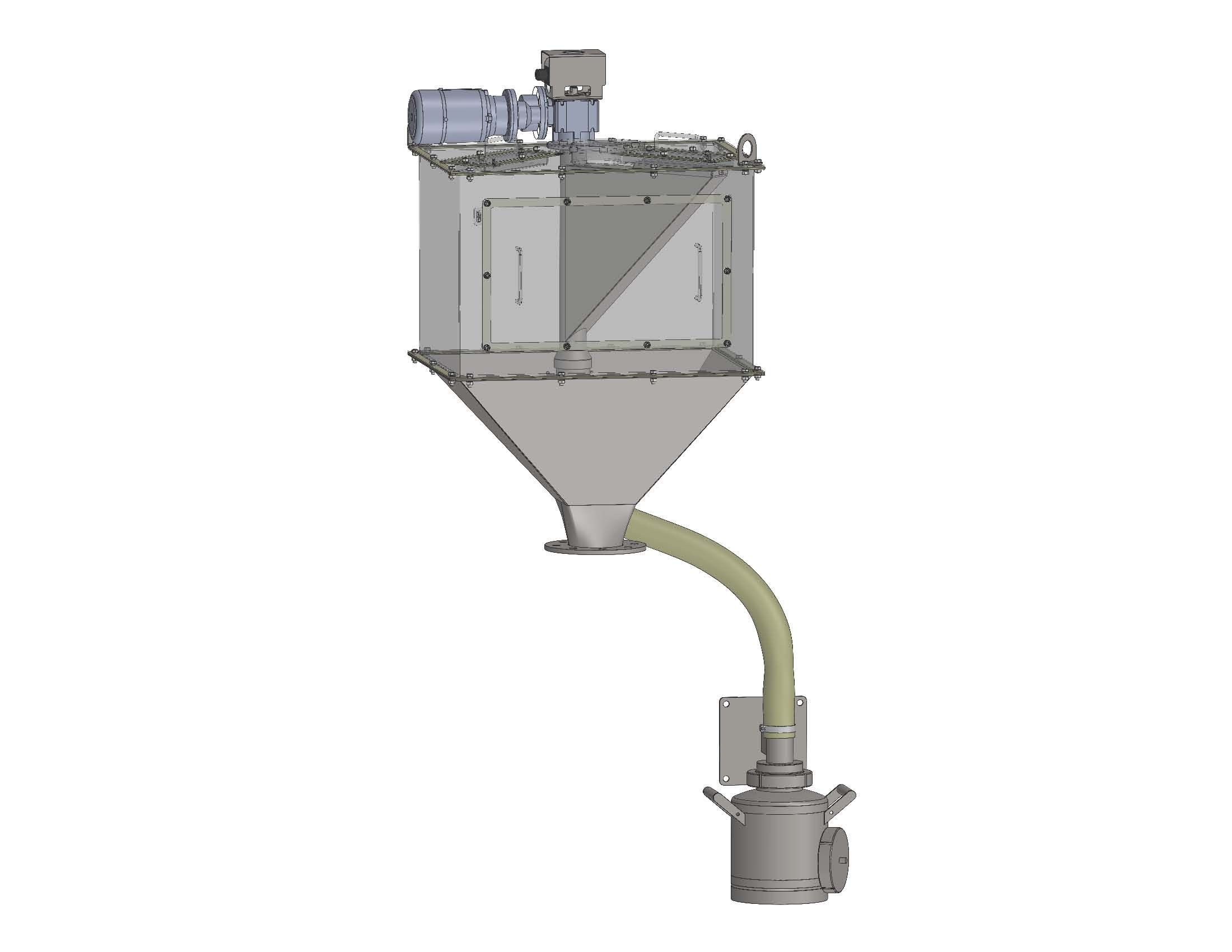

We design and make samplers for bulk materials directly for our customers´ applications, from simple manual samplers to complex equipment with automatic sampling, homogenisation and sample division, including the return of unused material to the production process.

Thanks to an individual approach to each application, we are able to successfully meet various customers´ requirements for the sample size, sampling frequency, sample labelling, etc. Our samplers can be used in various areas, from the power industry to the chemical and food processing industries.