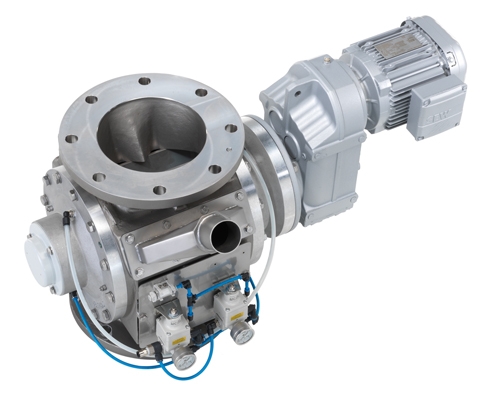

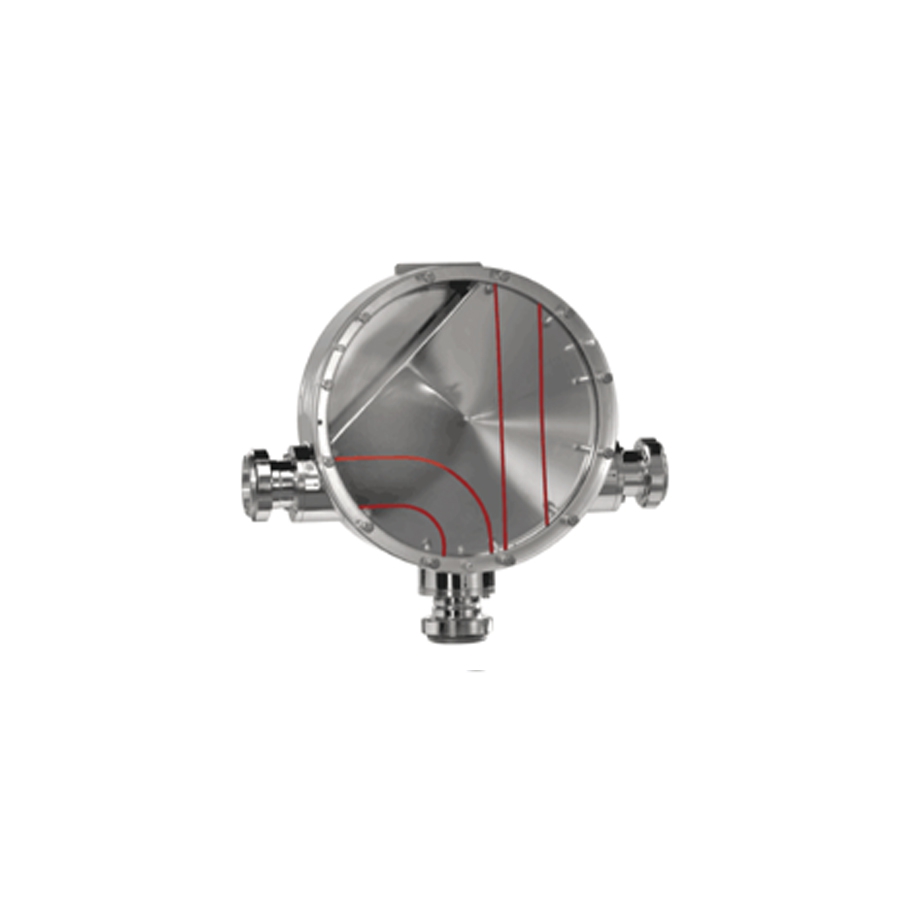

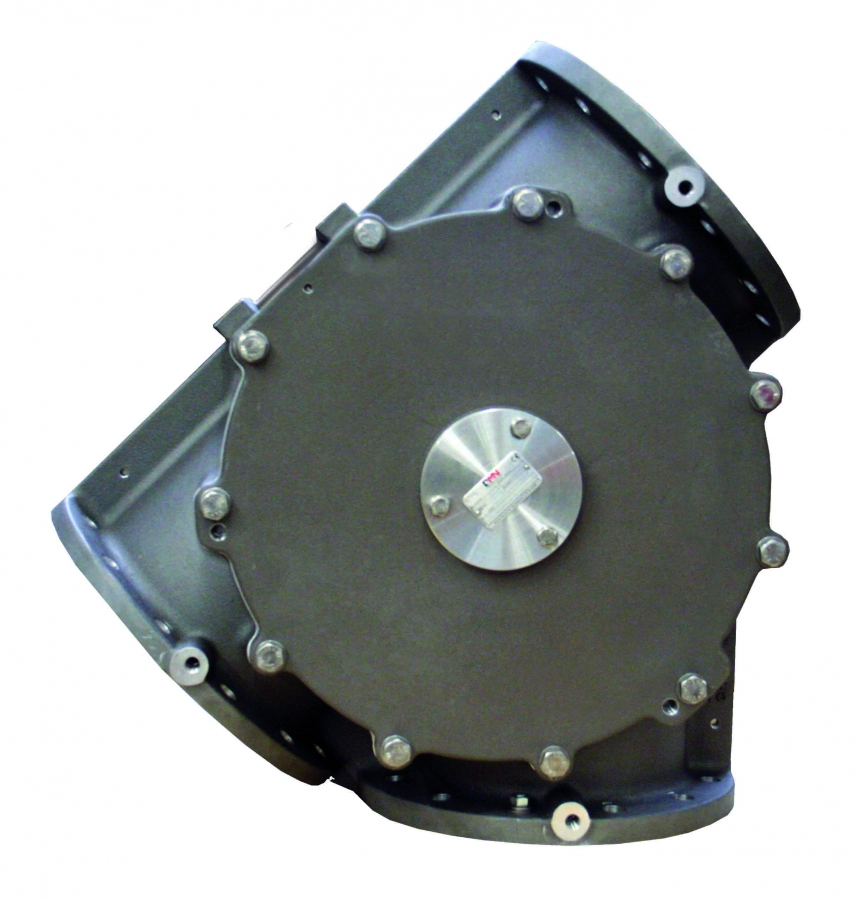

Rotary feeders and diverter valves

Custom-made designs of rotary feeders and diverter valves by the company DMN Westinghouse ,with over 40 years of tradition, can be used in any industry where bulk materials are to be handled.

Rotary feeders and diverter valves delivered by our company consist of a number of universal components suitable for a wide range of applications. We also offer a number of special components that can be used in a specific industry or to handle specific products.

We deliver rotary feeders and diverter valves as separate pieces of equipment or as part of complete technological units, such as, e.g., pneumatic conveying systems, etc.